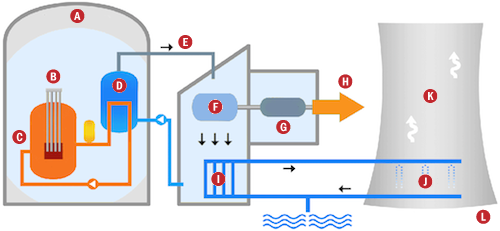

A nuclear reactor is a device where a controlled nuclear chain reaction takes place, and energy is released. Nuclear reactors are used in nuclear power plants for generating electricity, and also in the propulsion ships or submarines.

Energy is released in nuclear reactors in the form of heat. This heat can be converted into a form of energy that can be used by society. In a typical nuclear power plant, this can be as simple as boiling water to produce steam that turns turbines to run electrical generators.

The chain reaction in a nuclear reactor is exactly critical, so, on average, just one neutron from each fissioning nucleus leads to fission in another nucleus. To make this possible, the reactor core contains several components that are used to maintain the criticality conditions.

Neutrons released in fission have about 1-2 MeV of energy. Such fast neutrons have a very low probability of causing fission of 235U and so these neutrons will pass by many, many nuclei before being absorbed by one of them and inducing fission. One solution is to slow them down, such that they have energies of the order of a fraction of eV.

One can think of the higher probability as arising from the fact that slow neutrons spend a longer time in contact with the Uranium nucleus. We call such neutrons thermal neutrons, because their kinetic energies are close to the kinetic energies of the molecules in the air around us. To slow down neutrons in a fission reactor for example, one fills the voids between the fissile material with a so-called moderator, for example water or graphite.

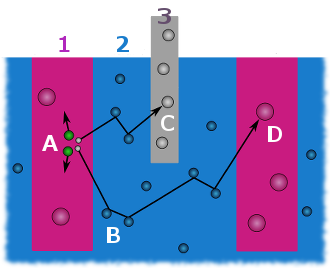

A reactor which runs on thermal neutrons is called thermal reactor. The diagram on the right shows the main components (1-3) of and processes (A-D) in a thermal reactor: (1) fuel rod, (2) moderator, (3) control rod, (A) fission, (B) moderation, (C) absorption in control rod, (D) capture in fissile material.If a neutron collides with a nucleus, the neutron could scatter in any direction, including out of the active area. Therefore, surrounding the fissile material with a non-absorbing substance that will scatter the neutrons back increases the number of possible collisions.

Steel, beryllium or graphite are common reflector materials. A reflector made of a light material like graphite or beryllium will also act as a neutron moderator, reducing neutron kinetic energy, while a heavy material like lead will have less effect on neutrons' energy.

The animation on the left illustrates the effect of a reflector material.We want to have the energy production as efficient as possible. However, if the efficiency is too high, one could end up with a nuclear explosion, a situation to be avoided! Nuclear reactors are built so that a nuclear explosion is not possible. To reach this goal one has to have the possibility of hindering a chain reaction if it develops too rapidly. This is achieved by dividing the fissile material into masses smaller than the so-called critical mass, so the neutrons will not find fissile nuclei as readily. The uranium pieces in question are then called subcritical.

Neutrons can easily escape from the uranium surfaces, before any dangerous build-up of energy is possible. In addition, in between the blocks of fissile material one can position so called control rods that strongly absorbs neutrons. The deeper the control rods are inserted in between the fissile material (fuel rods), the more difficult it is for neutrons produced from fission to collide with another uranium nucleus, resulting in a more limited chain reaction, and a decrease in the energy production.

The animation on the right illustrates the effect of cadmium control bars in a fission reactor.Most thermal nuclear reactors use 235U as fuel. However, its low abundance in nature (0.72% of the natural uranium, mostly 238U) makes the chain reaction impossible when natural uranium itself is used. Therefore the reactor fuel must be enriched with 235U. The degree of enrichment in nuclear power and research reactors varies from about 2% to about 40%. In reactors of older types, especially the ones used in submarines, the enrichment could even exceed 90%.

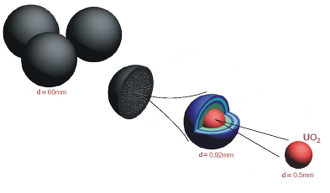

The fuel can be prepared in the form of pellets of UO2, a few centimetres thick. These pellets are arranged in the form of fuel rods. One can also use various alloys of uranium with other metals, for example aluminium. One recent proposal is to use specially designed spherical nuclear fuel elements.

There are also reactors that employ fast neutrons. In such reactors, absorption of a neutron by 238U leads to the formation of fissile 239Pu. This plutonium isotope can be extracted from burnt fuel and used for production of so-called MOX fuel containing the two fissile materials, 235U and 239Pu.

By far the most popular reactors use water as a moderator and coolant. The Pressurized Water Reactor (PWR or their Russian version VVER) are of this type. Just as the pressure in a pressure cooker raises the boiling point of water, so happens in a PWR ... except that the pressure is immense, about 15MPa, so the water in the primary cooling system reaches temperatures as high as 600K without boiling! What boils in the steam generators is the water from a secondary circuit to which the heat from the primary circuit is transferred. Another version of reactor, Pressurized Heavy Water Moderated Reactor (PHWR), uses heavy water (D2O) as moderator. There are also so-called Boiling Water Reactors (BWR), in which water boils directly inside the reactor.

There are other types of reactors that make use of thermal neutrons:Gas Cooled Reactors in which carbon dioxide (CO2) or helium are used for cooling. The gas is pumped through channels in the graphite moderator.

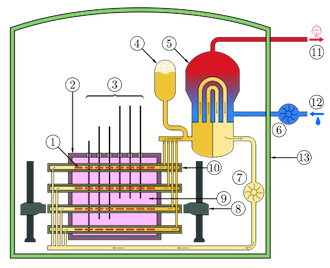

Canadian Deuterium-Uranium Reactor (CANDU) in which heavy water plays the role of moderator and coolant. Due to insignificant neutron losses in D2O, such reactors can use natural uranium as a fuel.

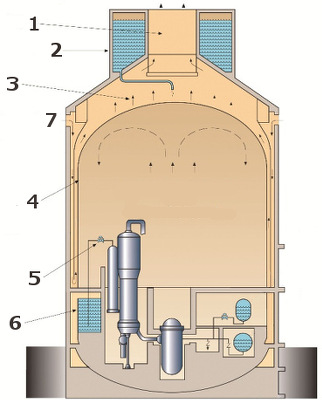

Schematic of a CANDU reactor: 1 - fuel bundle, 2 - reactor core, 3 - control rods, 4 - D2O pressure tank, 5 - steam generator, 6 - water pump, 7 - D2O pump, 8 - fueling servos, 9 - D2O moderator, 10 - pressure tube, 11 - steam to turbine, 12 - cold water from turbine, 13 - containment building (Image credits: Creative Commons)

High-powered pressure-tube reactors (RBMK) with graphite moderators were popular in the former Soviet Union because they could be used for production of weapons-grade plutonium (239Pu). This type of reactor was involved in the Chernobyl accident in 1986.Nuclear reactors may use fast neutrons of energies of 50-100keV. Such reactors typically have no moderators and can effectively produce fissile 239Pu that can then be reused as fuel. They may be cooled either by helium or liquid sodium and can be made quite compact, for example to be used on submarines. An example of a nuclear power plant working with a fast neutron reactor was SUPERPHENIX that operated in France from 1985 to 1997. Another reactor of similar, although not identical, breeder type (i.e. reactor that produces its own fuel) has been in operation in Sverdlovsk in Russia since 1981.

Most of the reactors operating today are of the IInd Generation. Very safe reactors of the IIIrd Generation have been designed recently, and IVth Generation reactors are already planned. In the last category, one can expect both gas-cooled and water-cooled reactors to be present, as well as a variety of reactors working with fast neutrons.

A particularly interesting project involves a high-temperature gas-cooled reactor with a core made up of 330000 spherical fuel elements, 60mm in diameter, each one composed of about 15000 grains of UO2.

In addition, water-cooled reactors of the IVth Generation also offer new safety features. Westinghouse Electric worked out the idea of an “international reactor innovative and secure‘ (IRIS in short). In such a reactor the whole primary cooling circuit is placed inside the reactor, so a serious loss of coolant is virtually impossible. One could also think about operating the reactor at a temperature and pressure above the critical point for water, i.e. under conditions in which there is no difference between a gas and a liquid. The excellent heat conductivity of water in such a state would enable one to achieve an efficiency of 45%, and, through the work being carried out at high temperatures, to produce hydrogen fuel.

Breeder reactors cooled by liquid metals offering high heat conductivity are also being considered. The coolant in this case would be kept under atmospheric pressure, so a violent release of the coolant in the event of a primary system break is excluded. However, the technical difficulties in handling liquid metals have hampered the development of these reactors. They remain however a strong candidate for future sustainable nuclear fuel cycle.

As some simple rules to keep a reactor safe one must:

1) Be able to shut it down when necessary

2) Keep the core covered with water

3) Keep the containment intact

In order to put into practice these general principles we use the natural laws of physics. If mechanical devices are used, one must provide at least two kinds of device, so that the same failure can not appear simultaneously in both.

Nuclear reactors feature multiple and redundant safety layers. The biological shield around the reactor protects people against ionising radiation produced in the reactor core. The water in PWR or PHWR reactors is carefully purified (distilled) since any impurities in the water could become radioactive during the operation of the reactor. The reactor itself is typically surrounded by heavy, thick concrete and situated within a purpose-built hall whose walls can sustain the pressure wave of the steam that would form in a serious accident. In addition, the buiding that houses the reactor hall has again heavy, thick walls. The roofs, often hemispherical, are strong enough to survive an aeroplane crash. Special attention is paid to the mechanics and control of the cooling system.

Reactor safety systems are often threefold, reducing the probability of simultaneous failure of all systems to practically zero. This is why there have been so few accidents in the history of nuclear power. The accidents at Three Mile Island in the USA, Chernobyl in the former USSR and Fukushima Daiichi in Japan are indeed exceptions where chains of multiple systems failure compounded with human error or natural cataclisms have overwhelmed the safety systems in place.

Last, but not least, special care is taken over both the nuclear waste and fissionable material stored close to the reactor, to safeguard against theft and misuse of the material (e.g. for nuclear weapons).

There is a fundamental difference between the explosion of a nuclear bombs and an explosion at a nuclear reactor! In fact, nuclear explosions are actually impossible in a nuclear reactor although ordinary thermal (from the steam) and chemical (from the hydrogen reacting with oxygen) mechanisms have led to the nuclear incidents at Chernobyl and Fukushima power plants. The main consequence of a reactor explosion is the release of radioactive material into the atmosphere which then forms radioactive fallout. The distribution of the fallout will depend on the weather conditions (wind and rain in particular).

What about the consequences of a terrorist aeroplane attack on a nuclear power plant? The containment enclosure would not suffer much damage in such an eventuality, and certainly the reactor core should not be affected. However, the cooling and electric power supply systems could suffer if hit. In spite of the present safety devices, this kind of damage could, in the worst scenario, lead to an overheating and melting of the reactor core. Even in such a case, however, the radioactive materials would stay within the pressure vessel of the reactor. What can be more dangerous is a successful attack on the high-level wastes repository situated at the nuclear power plant. Although such an attack would be difficult because of the rather small dimensions of these repositories, it is nevertheless not impossible. One can foresee that the radioactive materials would be scattered afterwards, though the problem would remain of a local scale only.